VAPOUR WET BLAST CLEANING

At MX Engines we offer a Professional Vapour Wet Blast Cleaning Service.

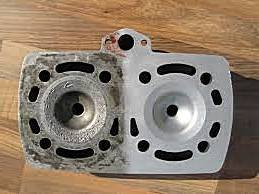

Vapour Blasting is sometimes called by other names such as Wet Blasting, Wet Bead Blasting, Aqua Blasting, Vaqua Blasting, Slurry Blasting or Vapour Honing. But regardless of the name the process results in a clean, consistent finish, with no embedded particles or clinging dust, as you get with SAND BLASTING.

Our Vapour Wet Blasting process utilises very fine glass beads mixed with water to form a slurry, which is directed by compressed air to the item being cleaned, creating a scrubbing action on the surface of the material being cleaned, unlike Sand Blasting that uses a course sand media. Wet Blasting uses the WATER AS THE CLEANING AGENT and does not cause surface damage to the component. Therefore sensitive areas, such as threads and seal surfaces do not have to be protected before being wet blasted.

Our unique Vapour Wet Bead Blasting process is suitable for both ferrous and non-ferrous materials and can be used safely on automotive, aviation or marine parts, including soft aluminium.

We have a range of different bead sizes to choose from, depending upon the finish you want to achieve, anything from a shot peened look to a mirror finish.

We can clean items up to 1m x 1m x 90cm, and this process can be used on a wide range of vehicle parts etc., such as:-

- Engine Cases

- Engine Blocks

- Engine Heads

- Brake Calipers

- Fork Legs

- Wheels / Rims

- Hubs

- Frames and Swing Arms

- Carburetors

- Radiators

- Many other aluminium and steel components

- Many non-vehicle related items

- Etc.

Please note we do not clean whole engines because of the risk of media entering the engine.

Vapour Wet Blasting Applications

- Degreasing / surface finishing of components such as engine cases and side covers.

- Removal of paint, rust, scale, carbon and similar deposits.

- Surface preparation prior to painting or coating.

- Satin finishing of stainless steel and other special materials.

- Improved engine performance.

- Or just for improved appearance.

Advantages of MX Engines' Vapour Wet Blasting process

- High speed gentle process for any metal.

- Dust free process.

- Cleans by flow of water not by impact.

- Water acts as a lubricant between the media and the component producing a 'softer' finish that also avoids media impregnation on soft materials.

- Gives a finish you could never achieve by hand.

- The best and safest cleaning for all surfaces.

Costs

Give us a call on 0439 389 152,

or complete the "Enquiry Form" opposite,

or bring your parts in for a cleaning estimate.

More Examples